Today

8:00 am - 4:00 pm

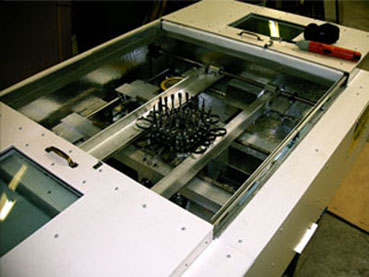

Cut to Length Machine

The operator uses the touch screen to set the length of the part to be cut.

This cutter will not accumulate the length of cuts.

There is a sensor that reads a UV dot on the part; this sets the cut.

The cutter will cut 65 parts per minute.

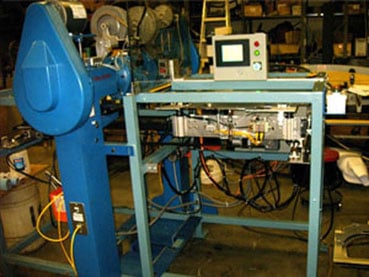

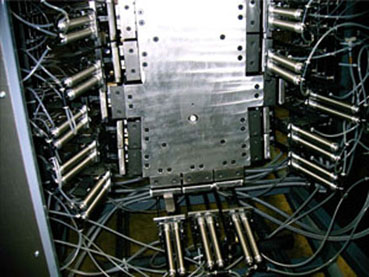

Biaxial Drawing Machine for Rutgers University

4" sample is clamped and heated up to 400F

Biaxial Drawing Machine for Rutgers University

Sample is stretched at settable speeds to 20" x 20" to change molecular properties.

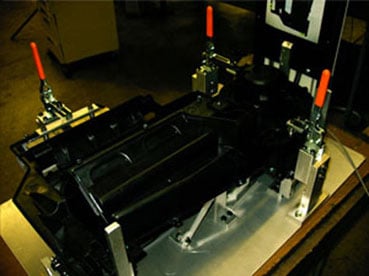

Dual Stapler Machine

Steel blank is placed into tray with mat and clamped

Dual Stapler Machine

Plastic mat is stapled to blank - 4 by front stapler, 5 by rear stapler.

Hemming Machine for Sound Deadening Form

Aluminum foil/foam sandwich edge tabs are automatically crimped.

Hemming Machine for Sound Deadening Form

Blank is loaded, held and all tabs folded and crimped simultaneously.

Poka-Yoke Fixture for Air Filter Assembly

Filter is inserted into slot and moves past camera.

Poka-Yoke Fixture for Air Filter Assembly

LED's show status of items checked - # of bars, filters present and placement.

Poka-Yoke Cooling Fixture

Part from press is clamped in fixture.

Poka-Yoke Cooling Fixture

Cooling fans are used to keep part straight.

Holes are checked for flash and shown on LED display.

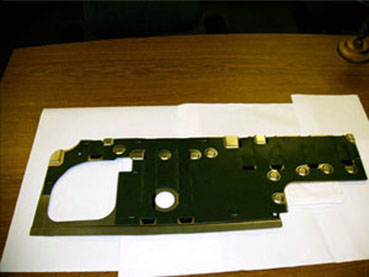

Poka-Yoke Fixture for Molded Transmission Housing

Checks for proper insertion of steel bushing.

Poka-Yoke Fixture for Molded Transmission Housing

Accepted parts are paint marked.

Rubber Extrusion

Cut to Length Line - Preset lengths up to 20' - automatic operations.

Rubber Extrusion Cut to Length Line

Measuring conveyor before shear.

33' Surface Winder

Plastic sheet rolled onto 6" OD core.

33" Surface Winder

End winder guide posts - adjustable for roll length.

Cut to Length Machine

The operator uses the touch screen to set the length of the part to be cut.

This cutter will not accumulate the length of cuts.

There is a sensor that reads a UV dot on the part; this sets the cut.

The cutter will cut 65 parts per minute.

Biaxial Drawing Machine for Rutgers University

4" sample is clamped and heated up to 400F